Introduction

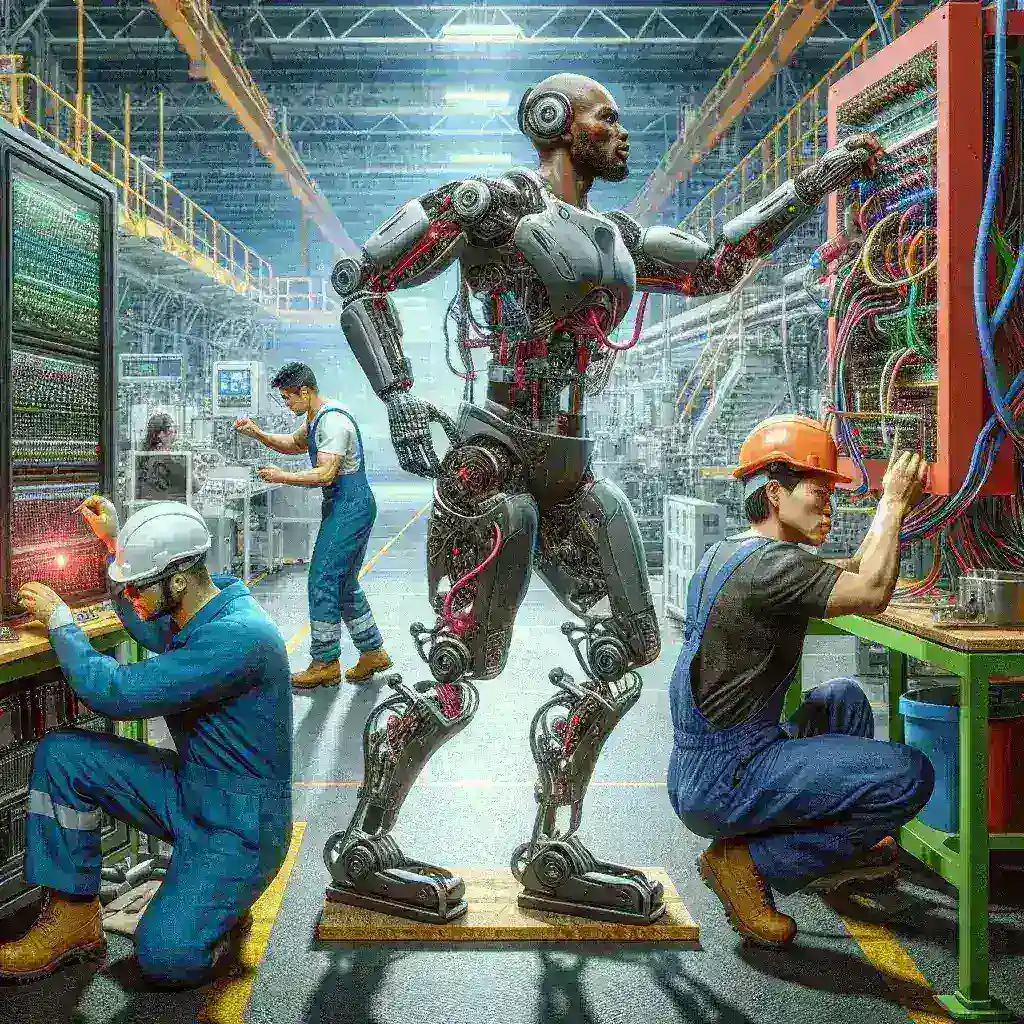

In the fast-paced and physically demanding world of manufacturing, workplace injuries are a persistent challenge. With the increasing focus on employee well-being and productivity, companies are turning to innovative solutions to mitigate these risks. One such groundbreaking solution is the advent of industrial exoskeletons. These wearable devices are designed to support and enhance human strength, enabling workers to perform physically demanding tasks more safely and efficiently. In this article, we will explore how industrial exoskeletons reduce workplace injuries in manufacturing settings, their benefits, potential drawbacks, and the future of this technology.

Understanding Industrial Exoskeletons

Industrial exoskeletons are wearable mechanical devices that can augment the physical capabilities of the wearer. They come in various designs, including full-body suits and partial systems that target specific body parts such as the back, arms, or legs. By providing support and reducing the strain on the musculoskeletal system, these devices can help prevent injuries and increase productivity.

The Mechanics Behind Exoskeletons

Most industrial exoskeletons use a combination of sensors, motors, and actuators to assist the worker in their movements. When an employee bends, lifts, or carries heavy objects, the exoskeleton activates to provide support, thereby reducing the load placed on the body. This assistance can significantly lower the risk of common workplace injuries such as sprains, strains, and musculoskeletal disorders.

The Impact of Workplace Injuries in Manufacturing

Workplace injuries are not just a matter of employee health; they also have a significant impact on productivity, morale, and overall business performance. According to the Bureau of Labor Statistics, manufacturing consistently ranks among the industries with the highest injury rates.

- In 2020, the manufacturing sector reported over 300,000 nonfatal workplace injuries.

- Musculoskeletal injuries accounted for a significant percentage of these cases, often resulting from repetitive motions or incorrect lifting techniques.

- Workplace injuries can lead to increased absenteeism, decreased productivity, and higher workers’ compensation costs.

How Industrial Exoskeletons Reduce Workplace Injuries

1. Enhanced Support and Stability

Industrial exoskeletons provide workers with enhanced support and stability during physically demanding tasks. By redistributing the weight of heavy loads, these devices help to alleviate the strain on the back and joints, reducing the likelihood of injuries.

2. Improved Ergonomics

Exoskeletons are designed with ergonomics in mind, promoting healthy posture and movement patterns. This focus on ergonomic design helps to prevent injuries caused by repetitive motions and improper lifting techniques.

3. Fatigue Reduction

By assisting with lifting and carrying tasks, exoskeletons can help reduce physical fatigue among workers. Less fatigue means a lower risk of accidents and injuries, as employees are less likely to make mistakes when they are not overexerted.

4. Increased Worker Confidence

When workers feel supported by technology, their confidence in performing physically demanding tasks increases. This newfound confidence leads to better performance and fewer accidents, contributing to a safer work environment.

Real-World Applications and Success Stories

Many manufacturing companies have started integrating industrial exoskeletons into their operations, with remarkable results.

Case Study: Ford Motor Company

Ford has implemented exoskeleton technology in various manufacturing facilities to assist workers in performing repetitive tasks such as lifting heavy parts. The company reported a significant reduction in back pain incidents among employees wearing exoskeletons, leading to improved productivity and job satisfaction.

Case Study: Boeing

Boeing adopted exoskeletons during the assembly of aircraft components. Workers reported feeling more comfortable and less fatigued, resulting in fewer injuries and increased efficiency on the production line.

Pros and Cons of Industrial Exoskeletons

Pros

- Injury Prevention: The primary benefit of exoskeletons is their ability to reduce workplace injuries, particularly musculoskeletal disorders.

- Increased Productivity: With the assistance provided by exoskeletons, employees can work more efficiently, completing tasks faster and with less effort.

- Cost-Effective: Although the initial investment in exoskeletons can be significant, the long-term savings from reduced injury rates and associated costs can be substantial.

Cons

- Initial Investment: The upfront cost of purchasing and implementing exoskeleton technology may deter some companies from adopting it.

- Training Requirements: Employees need proper training to use exoskeletons effectively, which can involve time and financial resources.

- Comfort and Fit: Not all exoskeletons will fit every worker comfortably, and ensuring the right fit is crucial for maximizing benefits.

The Future of Industrial Exoskeletons

The future of industrial exoskeletons looks promising as technology continues to advance. With the integration of artificial intelligence and machine learning, exoskeletons are expected to become more adaptive and responsive to the user’s movements, further enhancing their effectiveness.

Predictions for the Next Decade

- Increased Adoption: As more companies recognize the benefits of exoskeletons, their adoption will likely become standard practice in manufacturing settings.

- Technological Advancements: Future exoskeletons may feature improved sensors and feedback mechanisms, allowing for seamless interaction between the user and the device.

- Broader Applications: Beyond manufacturing, exoskeletons may find applications in healthcare, logistics, and construction, further expanding their impact on workplace safety.

Conclusion

Industrial exoskeletons represent a transformative approach to reducing workplace injuries in manufacturing settings. By providing enhanced support and promoting ergonomic practices, these innovative devices are helping to create safer and more productive work environments. As technology continues to evolve, the potential for exoskeletons to revolutionize the industry is immense. Investing in this technology not only benefits workers but also contributes to a more efficient and successful manufacturing landscape.